Reasons and solutions for deviation of saw blade

Time:2019-05-14 14:37:05Browse:0

The new alloy saw blade has passed the qualified inspection at the factory, and generally there will be no deviation. Only after improper use will the deviation occur.

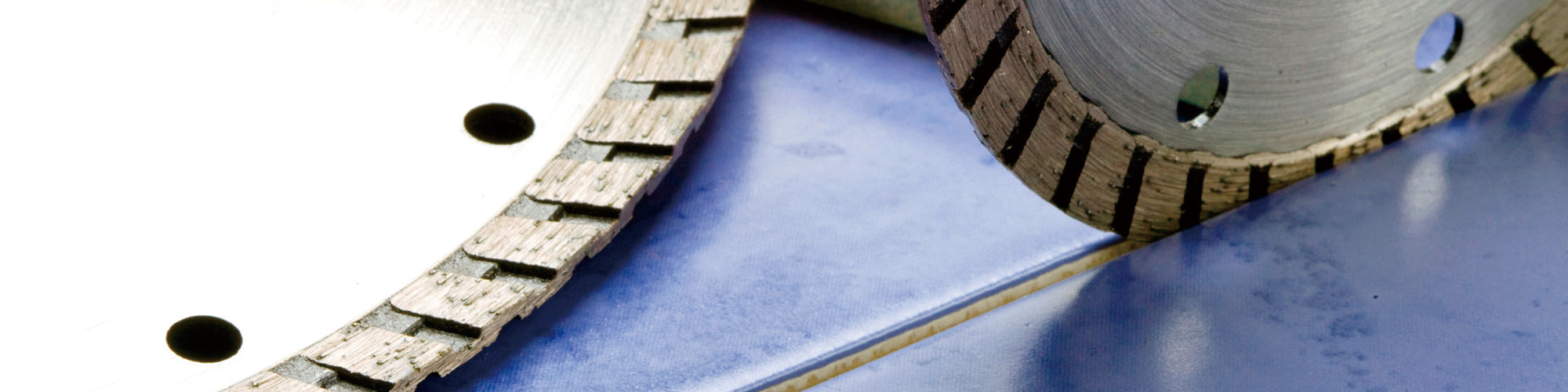

The reason for the deviation is that the alloy saw blade is not installed correctly, which will cause the saw blade to run sideways. In this case, the saw blade should be re-adjusted. The unilateral serrations are severely damaged, and the eight-junction has a damaged sawtooth. After the barbaric operation, the saw blade is deformed, and the eight-junction has a plastic repair.

The alloy saw blade is blunt, and it is used after the eight-blade cutting tool is ground. If the feed speed is too fast, it will also affect the feed direction and slow down the feed speed.

Because the material of the manufactured product is metal, in order to ensure the quality of the product, it is necessary to pay attention to placing it in a suitable environment, which can save resources and bring us great benefits.

Grinding and maintenance of saw blades

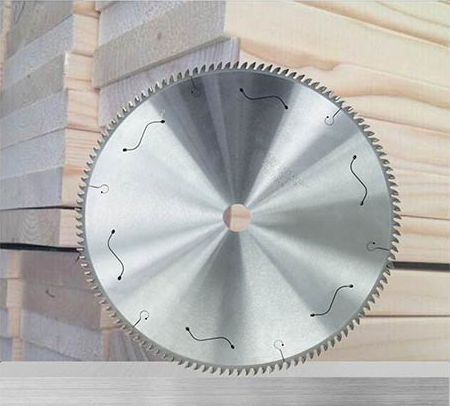

When purchasing the saw blade manufacturer's products, different saw blades should be selected according to the sawing direction, processing object and application occasions, and reasonable tooth number and tooth shape should be selected to ensure the sawtooth hardness, impact toughness, and cutting ability. Technical properties such as wear resistance.

In fact, improve the cutting quality of the workpiece, extend the durability of the circular saw blade and ensure the impact toughness and sharpness of the sawtooth; the size of the sawtooth has been scientifically calculated to minimize the welding residual stress, without false welding and desoldering. .

After the saw blade is used, the sawtooth has a chipping edge; the surface of the workpiece is fluffed; the sawing power is sharply increased. In order to ensure the quality and safety of the sawing, the skilled operator must re-grind and clean the circular saw blade in time and regularly remove the dirt on the serrated surface.

Through the understanding of the grinding and maintenance information of the saw blade manufacturer, we can help us better understand the performance of the saw blade and make the use of the saw blade get the best application effect, which is more favored by users.

Previous: dekton cutting blade for sale