How to judge the height of the diamond saw blade

Time:2018-12-10 16:18:12Browse:0

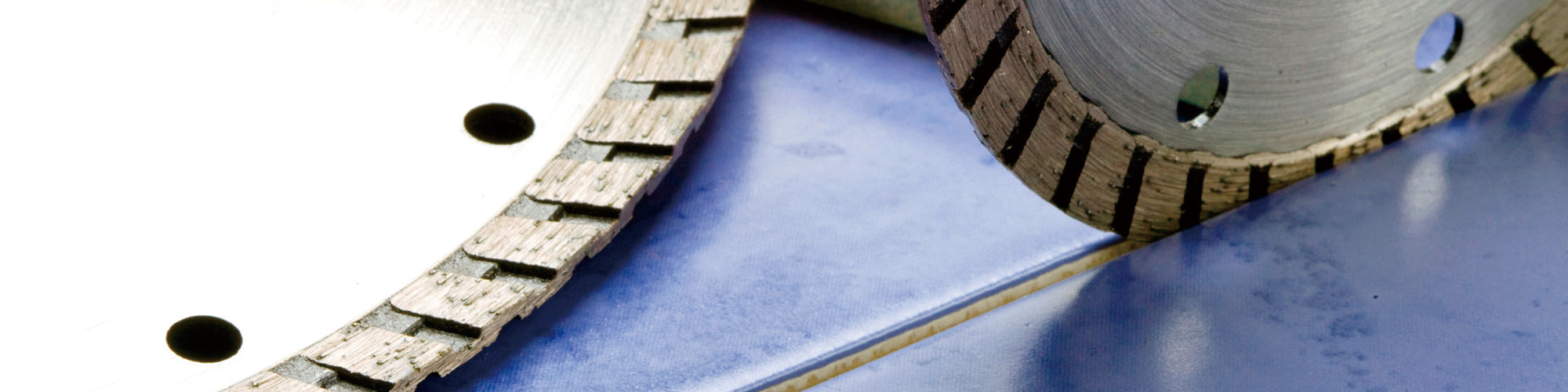

Generally speaking, the working environment of diamond saw blade is relatively harsh, the main use of the product is sawing stone, widely used in marble, granite, ceramic wall and floor tile and concrete products cutting, stone, building materials industry is important and widely used processing tools.Our company can provide ultra thin diamond saw blade and ceramic cutting saw blade or stone cutting diamond saw blade,you can buy it.

Circular saw blade cutting has the advantages of convenient operation, high efficiency and good machining quality. But the noise is bigger, the blade rigidity is poor. During the cutting process, the saw blade is prone to vibration and deviation, which leads to poor parallelism of the workpiece being cut. The spindle of the saw machine can not bear a large sawing force, so that the cutting process produces swing, and can not cut straight line, although increasing the thickness of the saw blade can improve its rigidity, but it is still difficult to ensure the parallelism of the slice. In addition, increasing the thickness not only increases the cost of the saw blade, but also increases the width of the saw seam and reduces the yield. The linear speed of cutting the outer circle is relatively high, which can reach 50m/s. The cutting depth is limited by the diameter of the saw blade, which generally does not exceed one-third of the diameter. At present, the depth of sawing generally does not exceed 1 meter.

The key to the quality of diamond saw blade is the granularity of diamond, which is one of the most important indexes to test the abrasion resistance and sharpness of diamond saw blade.

Specific application examples and matters needing attention of diamond saw blade in some cutting aspects:

1. In the new dressing table, wear the feed and finally exit. Many brittle diamond dressing tools are easily damaged when they come into contact.

2. Tilt Angle, 10 to 15 ° diamond dressing tools first, refers to the direction of wheel rotation.

3. Install, repair or firmly clamp the cutting tool dressing tool shall not be suspended for too long.

4. Make full use of cooling whenever possible. At the completion time, the coolant is poured into the contact point between the dressing tool and the grinding wheel.

5.Start fixing the wheels, which are usually in the middle.

6. Note: except for minor repairs. Except for the deepest repairs, except for oil repairs :0.001-0.002 inches. In addition, reinforcement :0.0005-0.001 in.

7. Select the appropriate lateral speed manually. Slower profile (roughness of the surface to be polished to the extent allowed).