tuck point saw blade and stone blade base selection

Time:2019-07-09 15:58:07Browse:0

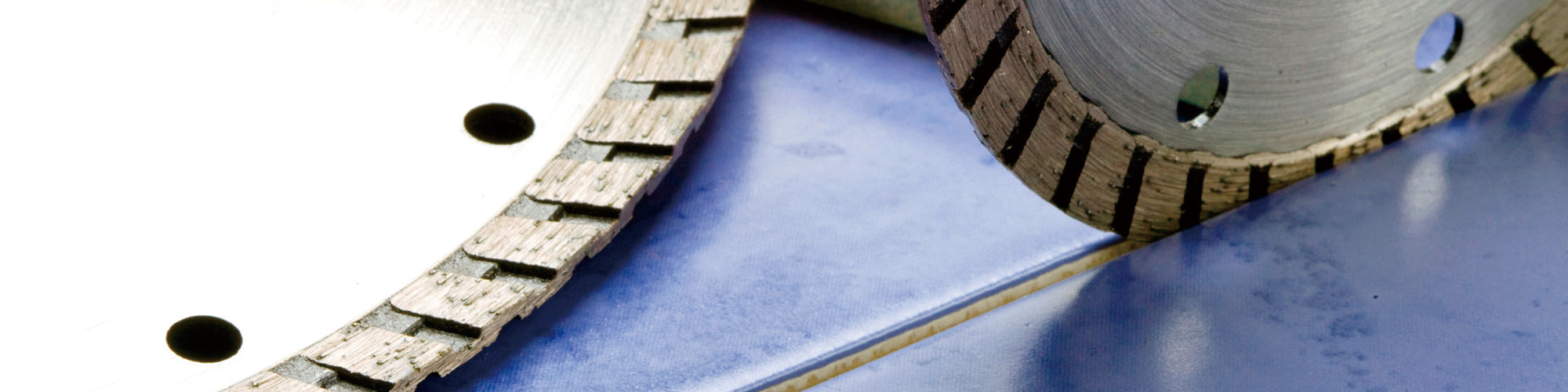

tuck point saw blade and stone blade base selection

The choice of the base of the saw blade, which is a general term for a circular tool for cutting solid materials. Saw blades can be divided into: diamond saw blades for stone cutting; high speed steel saw blades for metal material cutting (without carbide inserts)

1.65Mn spring steel has good elasticity and plasticity, economical material, good heat treatment hardenability, low heating temperature and easy deformation, which can be used for saw blades with low cutting requirements.

2.Carbon tool steel has high carbon and high thermal conductivity, but its hardness and wear resistance decrease sharply when it is heated from 200 °C to 250 °C. The heat treatment deformation is large, the hardenability is poor, and the tempering time is long and easy to crack. Produce economic materials such as T8A, T10A, T12A for tools.

3.Compared with carbon tool steel, alloy tool steel has good heat resistance, good wear resistance, good processing performance, and heat resistant deformation temperature is suitable for manufacturing high-grade alloy circular saw blades from 300 °C to 400 °C.

4.High-speed tool steel has good hardenability, hardness and rigidity, and low heat resistance. It is an ultra-high-strength steel and is thermoplastic and stable for manufacturing high-grade ultra-thin saw blades.

The basic requirements of the saw blade are the general term for the circular tool for cutting solid materials. Saw blades can be divided into: diamond saw blades for stone cutting; high speed steel saw blades for metal material cutting

1.Select the appropriate blade according to the design requirements of the device.

2.The equipment should be equipped with safety protection devices such as protective cover, power off brake and overload protection.

3.Have professional operators install and use, wear labored clothing, wear protective glasses, earmuffs, etc.

4.Operators should not wear gloves, long hair should be placed in the work cap, and tie and cuffs should be noted to prevent danger.

5.Keep away from fire and humid environments.we provide tuck point saw blade and stone blade,you can know it.

With reliable quality and excellent service, the company has a certain market at home and abroad, and has won good evaluation and high recognition from customers...

The company pursues sustainable development, creates brand products, and takes the enterprise spirit of "integrity, dedication, and forge ahead" to serve the customers better and faster!

Welcome friends from all walks of life come to call, visit, guide and business negotiations.

The choice of the base of the saw blade, which is a general term for a circular tool for cutting solid materials. Saw blades can be divided into: diamond saw blades for stone cutting; high speed steel saw blades for metal material cutting (without carbide inserts)

1.65Mn spring steel has good elasticity and plasticity, economical material, good heat treatment hardenability, low heating temperature and easy deformation, which can be used for saw blades with low cutting requirements.

2.Carbon tool steel has high carbon and high thermal conductivity, but its hardness and wear resistance decrease sharply when it is heated from 200 °C to 250 °C. The heat treatment deformation is large, the hardenability is poor, and the tempering time is long and easy to crack. Produce economic materials such as T8A, T10A, T12A for tools.

3.Compared with carbon tool steel, alloy tool steel has good heat resistance, good wear resistance, good processing performance, and heat resistant deformation temperature is suitable for manufacturing high-grade alloy circular saw blades from 300 °C to 400 °C.

4.High-speed tool steel has good hardenability, hardness and rigidity, and low heat resistance. It is an ultra-high-strength steel and is thermoplastic and stable for manufacturing high-grade ultra-thin saw blades.

The basic requirements of the saw blade are the general term for the circular tool for cutting solid materials. Saw blades can be divided into: diamond saw blades for stone cutting; high speed steel saw blades for metal material cutting

1.Select the appropriate blade according to the design requirements of the device.

2.The equipment should be equipped with safety protection devices such as protective cover, power off brake and overload protection.

3.Have professional operators install and use, wear labored clothing, wear protective glasses, earmuffs, etc.

4.Operators should not wear gloves, long hair should be placed in the work cap, and tie and cuffs should be noted to prevent danger.

5.Keep away from fire and humid environments.we provide tuck point saw blade and stone blade,you can know it.

With reliable quality and excellent service, the company has a certain market at home and abroad, and has won good evaluation and high recognition from customers...

The company pursues sustainable development, creates brand products, and takes the enterprise spirit of "integrity, dedication, and forge ahead" to serve the customers better and faster!

Welcome friends from all walks of life come to call, visit, guide and business negotiations.