Design principle of diamond saw blade

Time:2019-01-09 11:54:01Browse:0

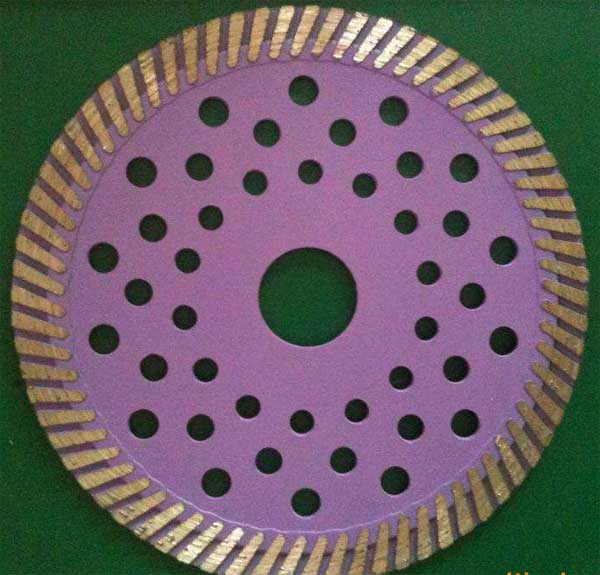

The diamond saw blade is a widely used processing equipment in the industry. In order to facilitate the understanding of the diamond saw blade, we will briefly introduce the design

principle of the diamond saw blade.we are diamond saw blade manufacturers.

The design principle of the diamond saw blade, the diamond saw blade is a special powder metallurgy product processed from diamond and metal powder, and some methods and means in the

conventional powder flashing are borrowed from the manufacturing. This kind of saw blade can guarantee the efficiency of work, but we can't guarantee the safety of the user

absolutely. Therefore, it is recommended that the preventive measures should be taken during the use time, but due to the speciality of diamond and the complex variability of the

processed object, it is more than normal. Powder flash products are more difficult to measure by mechanical performance standards. The factor that has a greater impact on the

performance of the cutter head is the binder.

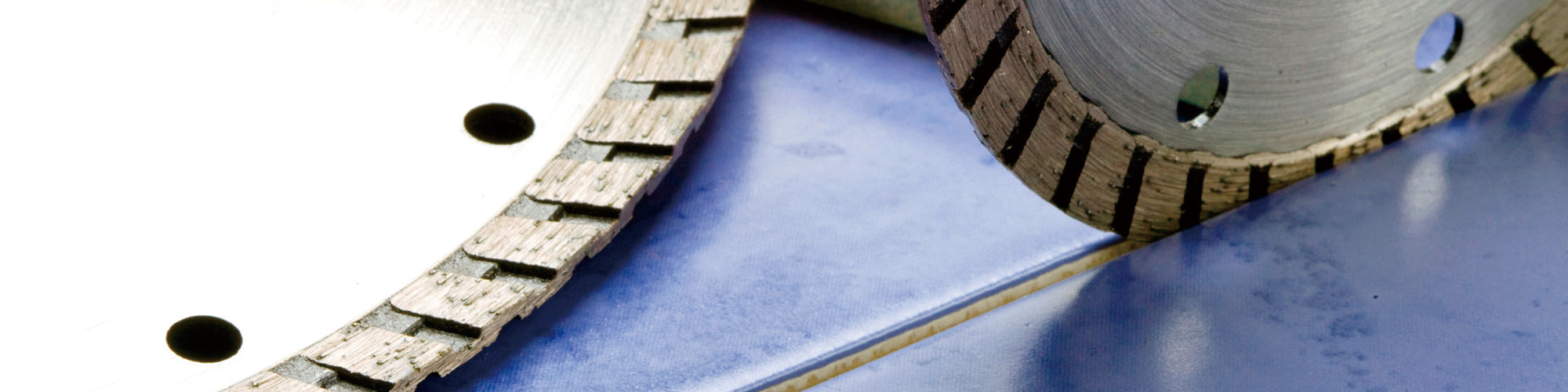

Diamond saw blade bond: The key points in the selection of saw blade bond in production research need to be considered, (1) the ability to hold diamond; (2) the coordinated wear of

diamond and bond for different processed objects; (3) suitable Manufacturing process conditions; (4) reasonable cost. The bonding agent has mechanical holding power and chemical

holding power for the holding force of the diamond. The mechanical holding power is mainly determined by the elastic modulus of the bonding agent. Elements that increase the modulus

of elasticity of the material, such as Cr, Mn, W, or WC hard phases, can increase grip and increase wear resistance. Of course, excessive wear resistance is not conducive to the

diamond edge. Chemical holding power is formed by the "welding" or chemical bonding of diamond to the binder. It not only improves the life of the cutter head, but also increases the

diamond protrusion height on the surface of the cutter head, forming a large cutting debris space and improving cutting efficiency. Increasing chemical holding power is to increase

the wettability and bonding of the bond to diamond.

After adding water to the diamond grinding disc, the conditions for its use will also be improved, which can effectively grind and polish ceramics, glass and stone, spiral diamond

grinding discs in sharpness, and heat resistance. It is better on the top, and it can be characterized by high brightness, fast glazing and not easy to fade without changing the

color of the stone itself.

Because high-tech products are becoming more and more widely used, and diamond soft-grinding tablets have been unanimously recognized by consumers in the whole stone processing

industry, but how to develop new markets for diamond soft-grinding films is still difficult to solve. However, the appropriate widening of the diamond softening disc in the scope of

principle of the diamond saw blade.we are diamond saw blade manufacturers.

The design principle of the diamond saw blade, the diamond saw blade is a special powder metallurgy product processed from diamond and metal powder, and some methods and means in the

conventional powder flashing are borrowed from the manufacturing. This kind of saw blade can guarantee the efficiency of work, but we can't guarantee the safety of the user

absolutely. Therefore, it is recommended that the preventive measures should be taken during the use time, but due to the speciality of diamond and the complex variability of the

processed object, it is more than normal. Powder flash products are more difficult to measure by mechanical performance standards. The factor that has a greater impact on the

performance of the cutter head is the binder.

Diamond saw blade bond: The key points in the selection of saw blade bond in production research need to be considered, (1) the ability to hold diamond; (2) the coordinated wear of

diamond and bond for different processed objects; (3) suitable Manufacturing process conditions; (4) reasonable cost. The bonding agent has mechanical holding power and chemical

holding power for the holding force of the diamond. The mechanical holding power is mainly determined by the elastic modulus of the bonding agent. Elements that increase the modulus

of elasticity of the material, such as Cr, Mn, W, or WC hard phases, can increase grip and increase wear resistance. Of course, excessive wear resistance is not conducive to the

diamond edge. Chemical holding power is formed by the "welding" or chemical bonding of diamond to the binder. It not only improves the life of the cutter head, but also increases the

diamond protrusion height on the surface of the cutter head, forming a large cutting debris space and improving cutting efficiency. Increasing chemical holding power is to increase

the wettability and bonding of the bond to diamond.

After adding water to the diamond grinding disc, the conditions for its use will also be improved, which can effectively grind and polish ceramics, glass and stone, spiral diamond

grinding discs in sharpness, and heat resistance. It is better on the top, and it can be characterized by high brightness, fast glazing and not easy to fade without changing the

color of the stone itself.

Because high-tech products are becoming more and more widely used, and diamond soft-grinding tablets have been unanimously recognized by consumers in the whole stone processing

industry, but how to develop new markets for diamond soft-grinding films is still difficult to solve. However, the appropriate widening of the diamond softening disc in the scope of

use is actually a good choice in the future development direction.